Hello friends, Today in this topic we are going to discuss types of gears and their uses.

If we are talking about types of gears then it can be classified according to

the axis of the shaft, on the basis of the velocity of the gear, on the basis of

types of gearing and the last is on the basis of the position of teeth on gear

surfaces.

Further, These are divided into different types of gear like spur gear, helical

gear, bevel gear, herringbone gear, etc, which will be known step by step

further in detail.

So without wasting time let's know the types of gears and their uses.

What is Gear?

Gears are a machine part that is stuck with another toothed part to transmit motion or change speed or direction.Different speeds can be obtained by using different joints of gears and shafts such as raising the torque, adjusting the speed and changing the direction of movement, etc.

Two or more gears that are doing one work behind another is called transmission.

Classification of Gear

Gear can be classified into the following categories:- According to the axis of the shaft

- On the basis of the velocity

- On the Basis of Type of Gearing

- On the Basis of the position of Teeth on Gear Surface

According to the axis of the shaft

According to the axis of the shaft, gears can be divided into the following types:- Parallel Shaft Gears

- Intersecting Shaft Gears

- Non parallel and Non Intersecting Gears

Parallel Shaft Gears

Spur Gears, Helical Gears, Herringbone Gears are parallel shaft gears.

Intersecting Shaft Gears

When two shafts of gear are intersecting with each other, they are called intersecting shaft gear.For Example,

Non parallel and Non Intersecting Gears

When two shafts of gear are non parallel and non intersect to each other, they are called intersecting shaft gear.For Example,

Spiral Bevel Gear

On the basis of the velocity

- Low Velocity Gear

- Medium Velocity Gear

- High Velocity Gear

Low Velocity Gear

When the velocity of the gear is less than 3m/s, it is called low velocity gear.Medium Velocity Gear

When the velocity of the gear is between 3 - 15 m/s, it is called medium velocity gear.High Velocity Gear

When the velocity of the gear is more than 15 m/s, it is called high velocity gear.On the Basis of Type of Gearing

- External Gear

- Internal Gear

- Rack and Pinion Gear

On the Basis of Position of Teeth on Gear Surface

- Straight Teeth Gear

- Inclined Teeth Gear

- Curved Teeth Gear

Straight Teeth Gear

This type of gear has straight teeth like spur gear.Inclined Teeth Gear

This type of gear has inclined teeth like helical gear, herringbone gear.Curved Teeth Gear

This type of gear has curved teeth like spiral bevel gear.So, now we are going to discuss step by step different types of gears and their uses.

Types of Gears and Their Uses

There are following different types of gears are used:- Spur Gears

- Helical Gears

- Herringbone Gears

- Bevel Gears

- Miter Gear

- Hypoid Gears

- Sprockets

- Face Gear

- Worm Gears

- External Gears

- Internal Gear

- Rack and Pinion

- Epicyclic Gears

- Involute splines

- Straight Sides Splines

Spur Gears

These are the most commonly used gears.In these types of gears, the teeth are made perpendicular to the bottom of the gear.

These gears are the types of the parallel shaft and straight teeth gear.

The benefits of spur gears are a simple design, cheap production, and maintenance.

These types of gears can bear only radial loads on

the bearings.

Spur gears are also said to be slow speed gears.

Spur gears can be used at almost any speed if noise is not a problem because these gears produced much sound as compared to other types of gears.

So, these types of gears are used where simple and small

works are performed.

You can also read the terminology of spur gear, law of gearing.

Helical Gears

Helical gears are almost like spur gears except that the teeth are not perpendicular to the bottom of the gear.The teeth are at an angle to the plane, causing the tooth area to have more contact in the same area as the helical gears.

Helical gears can be used to transmit motion even on parallel shafts. Teeth at the angle of helical gears attach more slowly than spur gear teeth.

Helical gears can carry more weight than spur gears of the same size.

Single helical gears exert both radials and thrust loads on their bearings, hence the use of thrust bearing.

These gears are used where heavy loads and high speed are required.

Herringbone Gears

Herringbone gears are like holding two helical gears together.So it is also called double helical gear.

An advantage of this is that it protects from side thrust, while helical gears produce side thrust.

In this type of gear, there is no thrust loading on the bearings.

Bevel Gears

Bevel gears are mostly used in situations where the power needs to be transmitted at right angles and two shafts cross each other.Bevel gears can be used at various angles, but most are tried at 90 ° angles.

The raw material for making bevel gears is conical in shape.

The gear ratio in bevel gear can be 10:1 to 500:1.

Bevel gears can be divided into two types:

- Straight Bevel Gear

- Spiral Bevel Gear

Straight Teeth Bevel Gear

Straight teeth bevel gears have tapers made in both tooth thickness and tooth height.Spiral Teeth Bevel Gear

It is also called skew bevel gear.

Miter Gear

It is a type of bevel gear and also transmits power at 90°.But the only difference is that in miter gear the gear ratio is 1:1 whereas in bevel gears the gear ratio can be 10:1 to 500:1.

Hypoid Gears

Hypoid gears look like spiral bevel gears except that the axes of the shaft do not intersect. They are designed to operate at 90 °.A gear ratio of 60:1 or more can be obtained from the same set of hypoid gears.

These types of gears are mostly used in automobile sectors.

Sprockets

Sprockets are used to drive chains or belts.They are typically used in conveyor systems.

Face Gears

Face gears often transmit power at right angles

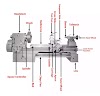

in power circular motion. Now, shown in figure worm gear, external gear, internal gear, and rack and pinion gear which is the most important types of gear and their uses described below.

|

| Types of Gears |

Worm Gears

Worm gears are used to transmit power at 90 ° where two shafts cross each other.The shafts of the worm gears are on a parallel plane and can also be skewed at any angle between the zero and the right angle.

The worm gear often meshes with a spur gear or a helical gear called a gear, wheel, or worm wheel.

Worm and gear sets are simple and compact means to achieve high torque, low-speed gear ratios.

External Gears

External gears are that type of gear, in which the teeth are formed on the outer surface of the cylinder or cone.Internal Gear

An internal gear is one in which the teeth are placed on the inner surface of the cylinder or cone.In these types of gears, large wheels are called angular rings, and small wheels are called the pinion.

Rack and Pinion

A rack is basically a straight gear used to transmit power and speed in a straight line.Torque can be converted into linear force by adding rack and pinion.

The pinion rotates and the rack moves on a straight line.

Such mechanisms are used to change the rotation of the steering wheel in automobiles to the left-to-right motion of the tie rod.

And these types of gears are also used in the lathe machine's bed and the table of the milling machine.

Epicyclic Gears

Examples of this are Sun and planet gearing and mechanical differentials.

Involute Splines Gear

Splined shafts are hubs that are often used as connectors in many different types of uses.Its biggest use is to connect motors with gears reducers.

They can also be used in transmissions.

Involute gears are similar to spur gears, but their pressure angles are different from them.

Straight Sides Splines

Straight Sides Splines often do the same thing as involute splines but instead of involute teeth, they have straight sides teeth.

So here I discussed types of gears and

their uses I hope you all enjoy this topic.

FAQ Related to Types of Gear

Which of the following type of gear have inclined teeth?

Helical gear is a type of gear that has inclined teeth thus the much more capacity to carry weight as compared to spur gear of the same size.

What is the most common type of gear?

The most common type of gear used in industry or any machine is spur gear because these types of gear can be used at any speed.

What type of teeth does a spur gear have?

In a spur gear mostly used straight or parallel types of teeth.

What is the difference between gear and pinion?

The main major difference between gear and pinion is that gear is used as a driver while pinion is used as a driven.

Herringbone gear can be used in parallel or intersecting shafts?

Herringbone gear is always used in parallel shafts, not in intersecting shafts.

It is also called double helical gear.

1 Comments