Hello Friends, In this topic we are going to discuss Lapping and Honing briefly.

At the end of this topic, we will also learn what is the difference between

lapping and honing.

Lapping and Honing both are the machining process which is used to improve the surface finish of any type of metal but there is some common difference between lapping and honing which we will know completely in detail.

So let's get started to know,

What is Lapping?

Lapping is a machining process that is used to improve surface finish by reducing roughness, waviness, and other types of irregularities on the surface.The process of making the metal surface more perfect is called lapping and with the help of Lapping Compound (Lap) is done to get a good finish on the metal surface.

Lap is flat or cheek, a metallic piece of any shape, which is soft with a finished workpiece.

Lapping dimensional accuracy is of a very high degree and can be done by hand or machine.

The metal can be cut from 0. 003 mm to 0.03 mm by lapping.

|

| Lapping |

Lap

A lap is a cutting tool that cuts the metal under the movement process and is often softer than the cutting metal.For making a lap generally using the cutting tool materials are copper, bronze, and forge steel.

Types of Lap

- Flat Lap

- Cylindrical lap

- Ring lap

- Floated or Spring Loaded Lap

Flat Lap

Flat lap made of soft gray cast iron and it has rectangular contoured shape.It is used for lapping flat surfaces.

Cylindrical Lap

It is made of a round shape with a hollow inside and its other name is expansion lap.It is used for lapping inner holes and ring gauges, etc.

Ring lap

Ring lap is used for lapping the outer cylindrical surfaces.Floated or Spring Loaded Lap

It is used to lap large-diameter cylinders or gauges.Charging Lap

Charging metals for laps like Emery, Corundum, Aluminum Oxide, Silicon Carbide, Diamond, etc. are widely used.During charging, firstly use lapping oil on the lap like machine oil, grease, kerosene oil, etc.

Then put abrasive material on the lap like aluminum oxide, silicon carbide, etc.

Then, Lap moves back and forth giving light pressure to the job.

There are the following abrasive materials used during charging the lap:

- Diamond

- Silicon Carbide

- Aluminum Oxide

- Boron Carbide

Diamond

Diamond is the most rigid abrasive, mostly used in rotary

lapping.

Silicon Carbide

It is used for removing excess material

like hard steel and cast iron.

Aluminum Oxide

It is used for high finishing and metal

cutting slowly.

Boron Carbide

It has a high cutting capacity.

Lapping Allowance

The allowance for the finishing process depends on the size and condition of the surface.

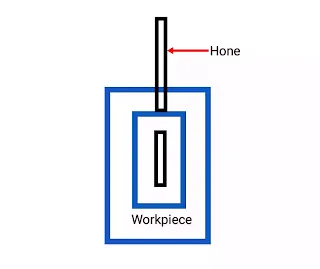

What is Honing?

It is an abrasive machining process used to finish the cylindrical surface of a metal workpiece by rubbing an abrasive grinding stone or grinding wheel with a controlled path.Honing is mainly used for engine cylinders, boring, pin holes, etc.

Honing operation is performed on a machine called honing machine.

Honing operation is often preferred for internal cylindrical surfaces, but honing can also be done on external surfaces.

|

| Honing |

- To bring a good finish and to make the bore of high grade.

- To increase the size of the bore.

- To fix the tolerance of the deformed bore during heat treatment.

Hone

The tool used for honing is called Hone.Hone is an abrasive stick made of materials used to make grinding wheels.

Bonding materials such as vitrified and

resinoid bonds are used for sticks with aluminum

oxide, silicon carbide, and diamond grit.

As a rule, hard sticks are used for soft materials and soft grade sticks are used for hard materials.

Types of Hone

According to their work and shape hone can be classified into the following types:- Rectangles Hone

- Triangles Hone

- Spheres Hone

- Semicircles Hone

Honing Machine

Honing machines can be divided into two classes.- Vertical Machine

- Horizontal Machine

Vertical Machine

Vertical machines that prevent the tilt of the workpiece and tool.Horizontal Machine

Horizontal machines can be worked on quickly and are more suitable for manual operations and long pieces.Honing operation

In a manual honing operation, it is common practice to hold the workpiece and move it back and forth over the tool, moving around the end of the spindle.Honing tool speed

Surface cutting speed is lower for hard metals and higher for soft metals as per a general rule.Honing Allowance

Two types of surfacing are often honed:- Fine-Turned

- Grinded

Grinded surfaces require less honing allowance, and turned surfacing requires more honing allowance.

Coolant for Honing

Turpentine, kerosene, and thin soluble oil solutions are good coolants for honing.Difference Between Lapping and Honing

There is the following difference between lapping and honing:| Lapping | Honing |

|---|---|

| In the lapping process, flats and outer cylindrical surfaces are preferred for a smooth finish. | In honing process internal cylindrical surfaces are preferred for a smooth finish. |

| Give fine finish like glass and It is finer than honing. | It is less fine than lapping. |

| IT 01 tolerance grade can be obtained in this process. | Up to IT 4 tolerance grade can be obtained in this process. |

| Sliding is not suitable for the surface because it has more adhesive. | Sliding is suitable for surfaces. |

| In lapping, process metal can be cut from 0.003 mm to 0.03 mm. | In honing process metal can be cut from 0.010 mm to 0.15 mm. |

| The lapping speed is slightly less than honing. | The honing speed is slightly higher than lapping. |

| Lapping slurry or fluid suspension of very small abrasive particles is used between the workpiece and the lapping tool. | Bonded abrasive sticks/stones are used. |

| The lap is pressed against the work and moved back and forth over the surface. | Honing stones are pressed against the work and given oscillatory and rotary motion. |

| Surface finishes of around 0.08 to 0.025 um or slightly better can be achieved. | Surface finishes of around 0.13 to 1.25um |

| Commonly used grit sizes are 300- 600. | Commonly used grit sizes are 100- 150. |

| The cutting mechanism is different than honing. | Bonded abrasives remove the material. Similar to as in grinding. |

| Used for external as well as internal cylindrical surfaces and flat surfaces. | Mainly used for internal cylindrical surfaces. However, its variant short-stroke honing or superfinishing is used for all types of surfaces. |

| Used in finishing of optical lenses, metallic bearing surfaces, gauges, etc. | Used in finishing of bores of internal combustion engines, bearings, hydraulic cylinders, gun barrels, etc. |

| It is done by using a lap or lapping compound. | It is done by using honing stone. |

| This operation is done with the help of a machine and manually. | This operation is done with the help of a machine. |

| Coolant is not important. | Coolant is most important. |

| A small amount of material is removed. | A large amount of material is removed. |

| During the lapping process, there is no burr produced. | During honing process burr can be produced. |

| Heat generation in the lapping process is negligible. | The heat is generated during the honing process. |

0 Comments