Hello, friends today you will learn what is tool life, Taylor's tool life equation, what are the factors affecting the tool life and at the last also we will know how to calculate tool life.

Tool life is a very important parameter of any cutting tool because through tool life we know how long this cutting tool will be used in it.

Tool life is calculated by Taylor's tool life equation, which we will know further in detail.

So without wasting time let's get started

What is Tool Life?

Tool life is the time period between two successive re-sharpenings with which the tool effectively cuts the material.

Tool life is an important factor in production work because a lot of time is lost whenever a tool is re-sharpened and reset on the machine.

Tool life is actual machining time by which a fresh cutting tool satisfactorily works after which it needs reconditioning or replacement.

Tool life based upon the criterion of the volume of material removed is derived as follows :

The volume of material removed per minute

V = π D × t x f × N (mm^3/min)

V = π D × t x f × N × T mm^3

Cutting Speed

C = [π D N] / 60 m/s

= [π DN]/1000 mm/min

πDN= 1000 C

Then also find out Volume of material

V = 1000 C × t x f × T mm^3

Where,

D=Diameter of the workpiece in mm

t= depth of cut in mm

F= feed in mm/rev

N=revolution of the workpiece in rpm

T= time for tool failure in min

V= Volume of material

Taylor's Tool Life Equation

Taylor's tool life equation As per F.W. Taylor, the relationship between Cutting Speed and Tool Life can be expressed as

VT^n = C

If V1, T1 initial condition and V2, T2 second condition then can be written as,

V1 × T1^n = V2 × T2^n

(V1/V2) = (T2/T1)^n

Where,

V= Cutting speed (m/min)

T= Tool life (minutes)

n= a constant whose value depends upon the material of the cutting tool & job, called tool life Index.

(Commonly, n=0.08 to 0.02 for H.S.S tools, n=0.2 to 0.4 for cemented carbide tools, n= 0.5 to 0.7 for Ceramic Tools, n = 0.1 to 0.15 for cast alloys)

C = a constant, called machining constant

Taylor's tool life equations modified version is,

VT^n × f^n1 × d^n2 = C

Where,

f = feed rate in mm/rev

d = depth of cut in mm

Cutting speed is the most important parameter which influences the tool wear and hence tool life.

Generally, the reduction in tool life corresponding to an increase in cutting speed is parabolic.

See in the figure when increasing cutting speed then tool life decreases.

|

| Cutting Speed Vs Tool Life |

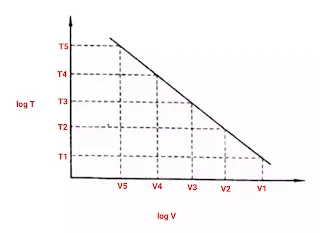

If the relationships between different cutting speeds and the corresponding tool life are plotted on a log-log graph, straight lines are obtained.

See in figure log-log graph,

|

| Tool Life Vs Cutting Speed |

So, we can also write as Taylor's tool life equation in the form of a log.

Taking both side log then we can write it,

log(VT^n) = log C

log V + log T^n = log C

log V + n log T = log C

It reveals that the tool life decreases with the increase in cutting speed.

Factor Affecting Tool Life

The various parameters affecting the tool life are:

- Cutting Speed

- Cutting Temperature

- Feed and Depth of Cut

- Tool Geometry

- Tool Material

- Workpiece Material

- Nature and Cutting

- Use of Cutting Fluids

- Operator's Skill

Cutting Speed

We already discuss above If increasing the cutting speed then tool life definitely decreases.

Cutting Temperature

If increasing the temperature of the tool then decreases the life of the tool.

Feed and Depth of Cut

If increasing the feed and depth of cut that causes friction will increases between the tip of the tool and workpiece which decreases the life of the tool.

Tool Geometry

If you are not making the proper rack angle, back rack angle, etc then also it will affect the life of the tool.

Tool Material

Tools are made with different materials like carbide, ceramic, high-speed steel, carbon steel, etc. Which are the various mechanical properties on which the life of the tool depends.

Workpiece Material

If the cutting tool is not selected according to the workpiece material, it also affects the life of the tool.

Nature and Cutting

Nature of material which type of environment cutting condition also affects the life of the tool.

Use of Cutting Fluids

If the cutting fluid is not used properly or of good quality, it will reduce the life of the tool.

Operator's Skill

Operators must be well skilled in operating machining processes otherwise tool life is likely to be reduced.

Calculation of Tool Life

Question

The machining cast iron use high-speed steel tool life of 50 minutes was observed with a cutting speed of 100 m/min. Determine the tool life with a cutting speed of 80 m/min. ? (n = 0.09)

Solution

Given Data

T = 50 min

V = 100 m/min

n = 0.09

For finding tool life firstly we have to calculate the machining constant

As we know,

Taylor's Tool Life Equation,

VT^n = C

Taking both side log then we can write it,

log V + log T^n = log C

log V + n log T = log C

Putting value,

log (100) + 0.09 log (50) = log C

2 + 0.1529 = log C

2.159 = log C

Then,

C = 144.2

Now we can find tool life at a speed of 80 m/min.

VT^n = C

80 × (T)^0.09 = 144.2

(T)^0.09 = 144.2/80

= 1.775

T = 587.31 min

So friends in this article you have to know what is tool life, what is Taylor's tool life equation, what are factors affecting the tool life, and also know how to calculate tool life with an example.

I hope you enjoyed this topic.

Faq Related to Taylor's Tool Life Equation

The Taylor tool life equation is used to calculate?

The Taylor Tool Life Equation is used to calculate the tool life of any type of cutting tool.

What is the relation between the tool life (t) in minutes and cutting speed (v) in mm/min?

The relationship between Cutting Speed and Tool Life can be expressed as VT^n = C

Where,

V= Cutting speed (m/min)

T= Tool life (minutes)

What is modified Taylor's tool life equation?

The modified Taylor's tool life equation is expressed as VT^n × f^n1 × d^n2 = C

Where,

f = feed rate in mm/rev

d = depth of cut in mm

What is Taylor's tool life index?

The constant value n is called Taylor's tool life index whose value depends upon the material of the cutting tool & the job.

Taylor's tool life equation n values?

Its value is different for different materials such as it varies from 0.08 to 0.02 for HSS tools and from 0.2 to 0.4 for cemented carbide tools.

0 Comments