Hello, friends today's topic is related to "Indexing in Milling Machine" in which you will learn what is indexing in milling machines, types of indexing heads, different indexing methods as well as their formula and calculation.

Indexing in a milling machine is mainly used to cut gear teeth accurately and equal spacing of the teeth of the gear.

It is also used for milling gears, splines, squares, cutting of flutes in reamers, drills and milling cutters, racks, grinders, etc.

So without wasting time let's get started.

What is Indexing in Milling Machine?

It is an operation to divide the circumference of a workpiece into equally spaced divisions.

This operation is performed on the milling machine by means of an indexing attachment called an indexing head or dividing head.

But nowadays CNC type milling machine is most widely used in the industry because this type of milling machine is fully automatic.

What is Indexing Head or Dividing Head?

A dividing head is an attachment used to rotate the job through a given angle, which is often equal divisions of a circle.

It works by converting the work to an angular position with respect to the cutter.

Types of Indexing Heads

Generally, the following types of dividing heads or indexing heads are used.

- Simple Indexing Heads

- Direct Indexing Heads

- Universal Indexing Heads

Simple Indexing Head

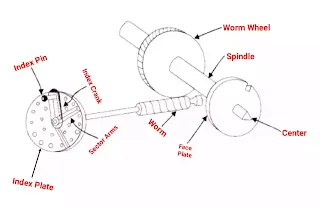

It consists of 40 tooth worm wheels attached to the spindle, single start worm, crank, and index plate.

40 turns of the index crank will make one revolution of the spindle.

One turn of the worm, the worm wheel spindle rotates 1/40 turn.

A fractional part of the worm wheel can be done using an index plate.

Parts of Simple Indexing Head

There are following parts are used in a simple indexing head.

- Index Plates

- Index Crank

- Crank Pin

- Sector Arms

- Worm Shaft

- Worm

- Worm Wheel

- Spindle

- Foot Stop or Tailstock

Index plates

An index plate is a circular plate with a series of equally spaced holes on it, to which the index crank pin is attached.

Index plate allows the worm to be moved in the fractional part of a turn.

Two types of Index plates are used.

- Brown & Sharp index plate

- Cincinnati Index Plate

Brown & Sharp index plate

It has contained three index plates

Plate no. 1 - 15, 16, 17, 18, 19 & 20

Plate no.2 - 21, 23, 27, 29, 31 & 33

Plate no.3 - 37, 39, 41, 43, 47 & 49

Cincinnati Index Plate

One index plate with eleven circles of holes on each side.

The plate is reversible and gives twenty-two cycles of holes.

First side - 24, 25, 28, 30, 34, 37, 38, 39, 41, 42 & 43

Second side – 46, 47, 49, 51, 53, 54, 57, 58, 59, 62 & 66

Index crank

The index crank is fitted to the end of the worm shaft.

The crank carries a spring-loaded index pin to engage the hole in the plate.

The crank is rotated by withdrawing the knob, turning the crank around a selected circle of holes, and releasing the knob to engage the pin in the required hole.

Sector Arms

There are two sector arms that fit on the face of the index plate.

The arms can be set apart to cover a required number of holes between them.

Direct Indexing Head

This indexing head consists of a spindle mounted in a housing that consists of a driving lug and an indexing crank.

Which has a flat index plate with several holes or slots fitted to the back or front of the housing.

Index plates usually have 24, 30, or 36 holes or slots.

The spindle is turned by hand and locked by a pin.

Universal Indexing Head

This indexing head is similar in principle to the simple indexing head.

Its ratio is 40:1.

An additional feature of this indexing head is that its spindle can be tilted from 0° to 90°.

There is a set of change gears is provided. As 24, 24, 28, 32, 40, 44, 48, 56, 64, 72, 86, 100.

There are three index plates, gear mounting brackets, spindle shaft, tailstocks, etc are also provided with it.

Any indexing operation of spur gear, helical gear and bevel gear, etc. can be performed.

Types of Indexing Methods

There are the following indexing methods employed in a milling machine.

- Linear Indexing

- Differential Indexing

- Angular Indexing

- Direct Indexing

- Simple Indexing

- Compound Indexing

Linear Indexing

To divide equal division of flat surface is called linear indexing.

Linear indexing is done on horizontal milling machines such as milling racks, steel rule graduations, etc.

Linear indexing is done by 2 methods

- By movement of a graduated collar of milling machine

- By using a dividing head on a milling machine.

By Using Dividing Head On Milling Machine

For precise longitudinal movement of the table, the dividing head spindle is connected with the machine table lead screw with a 1:1 ratio.

So in 40 turns of crank machine table lead screw is revolved a 1 turn and table moves equal to the pitch of the lead screw.

If the pitch of the table lead screw is 6 mm, in one turn of the crank table moves 1/40 of the pitch.

Table movement in 1turn of crank =

1/40 X 6 = 0.15 mm

Formula =( linear pitch of the job or workpiece X 40 Indexing movement)/( Lead of the table lead screw)

Calculation of Linear Indexing

Question

Calculate the indexing movement for index 0.12 mm linear pitch on the job while machine lead screw pitch is 6 mm?

Solution

As we know,

Indexing Movement =( linear pitch of the job or workpiece X 40 Indexing movement)/( Lead of the table lead screw)

Thus,

= ( 0.12×40)/60

= 4.8/6

You can clearly see that there is no matching hole in the given plate which is discussed above.

So, multiply with 10,

= 48/60 ( multiply with 10)

= 4/5

Now also the same condition so multiplying with 3.

= (4×3)/(5×3)

= 12/15

Thus, the index crank should be moved 12 holes out of 15 hole circle for each division.

Differential Indexing

Odd divisions which cannot be divisible by simple indexing are done by differential indexing.

Differential indexing is possible on Universal Indexing Head.

It is possible to index any number from 1 to 382.

Indexing of such odd divisions is done by simultaneously moving the index crank and index plate in the same or opposite direction.

In this method, the movement of the index plate is controlled by the turn of the index crank.

Arrangement of Index Head

For this method of indexing Universal Index head is used.

An extended spindle is fitted to the rear of the indexing head work spindle.

For this contact of index head spindle shaft and auxiliary worm, shaft is connected with change gears.

But before it back stops pin should be disengaged from the index plate.

The Formula for Differential Indexing

Index crank movement = 40/A

Where A is the assumed number which the nearer even number can be divisible by the simple indexing method.

Change Gear Set = (A – N)40 /A

= Driven/Driver

The change gear set available is, 20,24,28,32,40,44,48,56,64,72,86,and 100

Direction of Index Plate Movement

- If the assumed number is greater than the required number, the direction of the index plate and crank should same.

- If (A – N) is positive, the index plate rotates in the same direction.

- If the assumed number is less than the required number, the direction of the index plate and crank should be opposite.

- If (A – N) negative, the index plate rotate in opposite direction.

Rule for Added Idler Gear

For Simple Gear Train

- If (A-N )is +ve, the gear train is simple 1 idler gear is should be used.

- If (A-N) is -ve, the gear train is simple 2 idler gear is should be used.

For Compound Gear Train

- If (A-N) is +ve, the gear train is compound no idler gear is should be used.

- If (A-N) is -ve, the gear train is compound 1 idler gear is should be used.

Calculation of Differential Indexing

Question

Calculate the indexing movement and change gears for 55 divisions. (For simple gear train)?

Solution

Given Data - N = 55, A= 56

Index crank movement

= 40/A

= 40/56

= 5/7

no matching hole in the given plate so, multiplying with 3.

= (5×3)/(7×3)

= 15/21

Thus 15 holes out of 21 hole circles should be taken for each division.

Change Gear Set

= (A – N)40 /A

= {(56-55)×40}/56

= 40/56

These values match with the standard change gear set.

Thus gear train is simple, A-N is +ve, therefore 1 idler gear should be used

Angular Indexing

Process of dividing periphery of work in an angular measurement called angular indexing.

It is often necessary to index for a certain number of degrees when machining, keyways, grooves, flats, or other features located at angles to each other.

Angular indexing can be carried out using a simple indexing head attachment.

Angular Indexing Principle

Most indexing heads require 40 turns of the crank to rotate the spindle once.

One revolution of the spindle =360° or 40 turns of the crank.

If the crank is turned once the spindle rotates 1/40 of a turn and 1/40 of 360° is 360/40 = 9°

If follows that 1/9 turn of the crank will give a spindle movement of 1º.

Index crank movement Formula

= (Degree to be indexed)/9

Calculation of Angular Indexing

Question

Calculate index for 122°?

Solution

As we know,

Index crank movement

= (Degree to be indexed)/9

Thus,

Index crank movement

= 122/9

= 13 (5/9)

These values do not match with the plate hole so multiply with 2.

= 13(10/18)

Thus, 13 turns of index crank and 10 holes out of the 18 hole circles.

Direct Indexing

While a small number of divisions have to carry out direct indexing method is used. Such as making round to square, making round to hexagon, making round to octagon, etc.

For this method of indexing direct dividing head is used.

By this method, the numbers can able to complete divide the number of slots or holes of the index plate.

Formula for direct indexing

= (No of holes of index plates)/( No.of division required)

Calculation of Direct Indexing

Question

If 6 slots are to be machined and 30 holes on the index plate, calculate index movement?

Solution

As we know that,

Index crank movement = (No of holes of index plates)/ (No.of division required)

Thus,

= 30/6

Thus 5 holes are to be indexed every time.

Simple Indexing

Simple indexing is used to obtain a greater number of divisions that cannot be obtained by direct indexing.

It is also called plain indexing.

This operation may be performed in both simple and universal index heads.

Simple indexing can be used for all divisions up to 50, even numbers up to 100 except 96.

Formula for simple indexing

Index crank movement = 40/N

Calculation of Simple Indexing

Question

Find the number of turns of the crank required to index 12 divisions?

Solution

As we know,

Index crank movement

= 40/N

= 40/12

= 3 (4/12)

= 3 (1/3)

Thus index crank movement is done to 3 complete turns and 1/3 turn is required for each division.

Therefore, multiplying with 5.

Index crank movement = 3 (5/15)

So, 3 complete turns and 5 holes on 15 hole circle should be taken for each division is required.

Compound Indexing

When the number of divisions required is outside the range of simple indexing, and then compound indexing is used.

It involves the use of two different simple indexing movements and is followed in two-stage:

- Rotate the crank a certain amount in one direction, as in the case of simple indexing.

- Turn the index plate and crank both in the same or opposite direction, so further increase or decrease the speed obtained in the first stage.

Formula for Compound Indexing

Index Crank Movement

=( 40/N )= (n1/N1 )± (n2/N2)

Where,

N = no. of divisions required

N1 = hole circle used by Crank pin

N2 = hole circle used by the Lock pin

n1 = hole spaces moved by Crank pin in N1 hole circle

n2 = hole spaces moved by Plate and Crank pin in N2 hole circle

Calculation of Compound Indexing

Question

Calculate the indexing Movement for 27 divisions?

Solution

As we know that,

Index Crank Movement

=( 40/N )

= 40/27

Now, 40/27 can be written as follows,

(12/18) + (22/27)

Therefore, for indexing 27 divisions, 12 hole spaces moved by Crank pin in 18 hole circle and 22 hole spaces moved by Plate and Crank pin in 27 hole circle.

In this post, we’ve discussed What is Indexing in a milling machine, types of indexing heads, different indexing methods as well as their formula and calculation.

I hope you like this post.

Thank You.

0 Comments