Hello, friends Today's topic is related to "Grinding Machine" in which we learn 17 common types of grinding machines as well as their uses and grinding defects.

The grinding machine is widely used in small and large industries to grind any workpiece or a job.

Grinding is a finishing operation which is to gives the required accuracy and precision by removing the extra material.

Grinding is done on a grinding machine using a fast rotating grinding wheel to cut the material of a workpiece.

So without wasting any time let's get started.

What is a Grinding Machine?

Such a machine, on which grinding is done after fitting the grinding wheels properly, and which is used to perform the grinding process, that machine is called a grinding machine.

Classification of Grinding Machine

Basically Grinding machine can be classified into two categories which are:

- Non-Precision Grinding Machine

- Precision Grinding Machine

Non-Precision Grinding Machine

By this grinding machine, such materials are removed from workpieces that are rough such as materials made from casting, forging, etc.

Under this grinding machine comes a bench grinder, pedestal grinder, portable grinder, etc.

Precision Grinding Machine

By this grinding machine, such materials are removed from workpieces that are soft and required precise surface finished.

Under this grinding machine comes a surface grinder, cylindrical grinder, tool and cutter grinder, etc.

Types of Grinding Machine

Usually, the following types of grinding machines are used:

Non Precision Grinder

- Bench Grinder

- Pedestal Grinder

- Portable Grinder

- Flexible Shaft Grinder

- Swing Frame Grinder

Precision Grinder

- Surface Grinder

- Horizontal Spindle Reciprocating Table Horizontal Spindle Rotary Table

- Vertical Spindle Reciprocating Table

- Vertical Spindle Rotary Table

- Cylindrical Grinder

- External Cylindrical Grinder

- Internal Cylindrical Grinder

- Universal Cylindrical Grinder

- Centerless Grinder

- Tool and Cutter Grinder

- Special Purpose Grinding Machine

- Other Grinding Machine

- Wet Grinding

- Dry Grinding

See the types of non-precision grinding machines in the figure which are explained in detail below.

Bench Grinder

It is a small size grinding machine that is fixed on the bench.

A course and a fine wheel are usually fitted at both ends of this grinder.

Pedestal Grinder

This is a large size grinder with a pedestal.

A course and a fine wheel are fitted at each end.

It is fixed directly on the shop floor.

Portable Grinder

This is a small size grinding machine that has one wheel.

It can be taken to the place where grinding work is to be done.

Flexible Shaft Grinder

This grinder consists of a long flexible shaft at the end of which a grinding wheel is fitted, which is driven by a motor fixed to a fixed stand.

It is used for rough grinding works.

Swing Frame Grinder

This grinder consists of a 2 or 3-meter long frame with a grinding wheel that is suspended at its center of gravity so that it can move freely.

Now, See the precision types of grinding machines which are described below in detail.

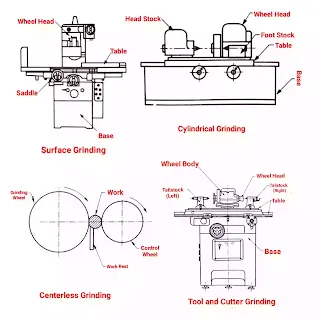

Surface Grinder

A surface grinder is a reciprocating grinding machine used for making flat surfaces on workpieces.

It can form surfaces with greater precision.

Types of Surface Grinding Machine

There are four types of surface grinding machines are used.

- Horizontal Spindle Reciprocating Table Horizontal Spindle Rotary Table

- Vertical Spindle Reciprocating Table

- Vertical Spindle Rotary Table

Horizontal Spindle Reciprocating Table

These types of surface grinding machines are mostly used as compared to other surface grinding machines.

It is made of a rectangular table that performs reciprocating motion to grind the workpieces and produce flat surfaces.

Horizontal Spindle Rotary Table

It is basically used for grinding round or thin workpieces.

Vertical Spindle Reciprocating Table

This type of surface grinding machine uses ordinary workpieces to produce flat surfaces.

Vertical Spindle Rotary Table

In this type of grinding machine, the workpiece is always rotated on the work table to make a flat surface.

But Horizontal Spindle Reciprocating Table Surface Grinding Machine is mostly used.

Cylindrical Grinder

Cylindrical grinders are used for grinding the outer or inner surfaces of cylindrical workpieces.

The diameter of the workpiece can be grinded to a close tolerance i.e. a surface finish up to 0.0025 mm can be achieved.

Types of Cylindrical Grinding Machine

Cylindrical Grinders are of the following four types :

- External Cylindrical Grinder

- Internal Cylindrical Grinder

- Universal Cylindrical Grinder

- Centerless Grinder

External Cylindrical Grinder

These types of grinding machines always grind the external surfaces of the workpieces.

Internal Cylindrical Grinder

These types of grinding machines always grind the internal surfaces of the workpieces.

Universal Cylindrical Grinder

These grinding machines are used when a workpiece is to be formed into a cylindrical or conical shape.

Centerless Grinder

A centerless grinding machine is a quick production machine in which the work is assigned to the centers but is held against the face of the grinding wheel by the combined action of the central wheel and supporting rest.

Its size is specified by the maximum of the job that can be grinded.

Tool and Cutter Grinder

It is a machine used for shaping and sharpening tools and cutters by means of abrasive wheels.

Universal tool and cutter grinders are often used for sharpening reamers, taps, single-point tools, dies, punches, and milling cutters.

Special Purpose Grinding Machine

These grinding machines are used to grind a specific workpiece.

Under this grinding machine comes a cam grinder, piston grinder, thread grinder, etc.

Other Grinding Machine

It may be precision or non-precision grinding machine.

- Wet Grinding

- Dry Grinding

Wet Grinding

In most of the grinding machines, there is a provision of a regular flow of coolant apparently on the workpiece where the wheel touches.

The flow of coolant causes the workpiece to cool to an irregular temperature.

It also cools the wheel and gives free cutting action and gives good results in finishing.

Dry Grinding

If there is no arrangement of coolant system with the grinding machine and the workpiece is finished on that grinding machine then it is called dry grinding.

Grinding Defects

There are the following grinding defects found during the grinding operation.

- Overheated Spots

- Chatter Marks

- Rapid wear of the Wheel

Causes of Overheated Spots

- The excess wheel speed and feed.

- Wheel in glazing condition.

- Not using enough coolant.

Remedies of Overheated Spots

- Use the right speed and feed.

- Dress the wheel.

- Use sufficient coolant.

Causes of Chatter Marks

- Wheel not mounted properly.

- Slackness in the spindle.

- Wheel unbalanced.

- Not clamping properly job.

- Excess cut depth for the machine.

Remedies of Chatter Marks

- Mount the wheel correctly.

- Remove slackness of spindle.

- Balance the wheel.

- Clamp the job properly.

- Use the correct cut depth.

Causes of Rapid Wear of the Wheel

- Wheel too soft.

- Grinding wheel speed is less than the permissible speed.

Remedies Rapid Wear of the Wheel

- Use the correct grade of the wheel.

- Increase the wheel speed to the approved speed.

So friends here we have to know 17 types of grinding machines as well as their uses, grinding defects.

If you like this post please share and also give suggestions through comments.

Thank You.

0 Comments