Hello, friends, Today's topic is related to "tool and cutter grinder" in which you will learn their parts, types, and uses.

In the machine shop, most of the machining operations are performed by a single-point cutting tool or a multipoint cutting tool.

Continuous use causes the cutting tool to become blunt and needs to be resharpening for continuous production.

Such resharpening is done by the tool and cutter grinder machine.

Tool and cutter grinders are used mainly to sharpen and recondition multipoint tools like drills, reamers, milling cutters, taps, hobs, broaches, etc, and for accurate grinding of angles of single-point tools.

With suitable attachment these grinders can also be used for light cylindrical surface, internal grinding operation on items like jigs and fixtures, gauge elements, etc.

But nowadays CNC type grinding is most widely used in the industry because this type of grinding is fully automatic.

So, without wasting time let's get started.

What is Tool and Cutter Grinder?

A tool and cutter grinder is a machine used for shaping and sharpening a tool or cutter by means of abrasive wheels.

It can be operated both hydraulically and electrically.

Parts of Tool and Cutter Grinder

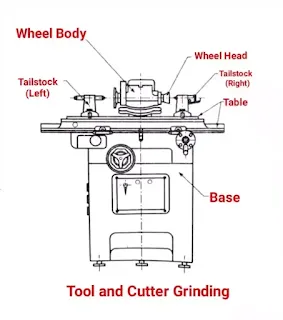

There are following parts are used in the tool and cutter grinding machine.

- Base

- Saddle

- Table

- Column

- Wheel Head

- Tailstocks

Show in the figure parts of the tool and cutter grinder which are described below in detail.

Base

It is strong heavy and box-type construction that supports all the other parts of the machine.

Saddle

It is mounted directly on the top of the base which carries the table raised and traverses the table movement crosswise.

Table

It rests or moves on the top base mounted on the saddle which reciprocates.

It can be swiveled from a certain angle.

Column

It is fixed on the back of the machine.

It has a wheel head that moves up and down depending on the depth of the cut.

Wheel Head

It is mounted on a column on the back of the machine which can be swiveled at a certain angle.

It has two grinding wheels which are fitted on both ends of the spindle.

Tailstocks

Right, and left tailstocks are placed between the centers to support the mandrel.

Types of Tool and Cutter Grinder

There are the following two types of tools and cutter grinders are used.

- Universal Tool and Cutter Grinders

- Single-Purpose Tool and Cutter Grinders

Universal Tool and Cutter Grinders

Universal tool and cutter grinder can be used for sharpening a variety of tools and milling cutters.

Universal tool and cutter grinders are often used for sharpening reamers, taps, single-point tools, dies, punches and milling cutters, etc

Single-Purpose Tool and Cutter Grinders

Single-purpose tools and cutter grinders are used for grinding tools such as drills, tool bits, etc. in a large production plant where the volume of production is a high and large number of similar tools need to be grind frequently.

Characteristic Of Tool & Cutter Grinder

There is the following characteristic of the tool & cutter grinding machine.

- It can be held the maximum diameter of the wheel.

- It can be grind the maximum height of the job or workpiece.

- It can be grind the maximum length of the job or workpiece.

- It can be grind maximum breadth of the job or workpiece.

Types of Grinding Wheels for Sharpening the Milling Cutter

Grinding wheels of the following types are often used for sharpening the cutters:

- Straight Wheel

- Dish Wheel

For straight wheels, grain size 36 or 46 should be selected.

The grain size for dish wheels should be between 36 and 80.

Abrasives (A), Grade (I to L), Structure (S), Bond (V) should be used to get good finishing.

Follow-Up Points for Sharpening Cutters

- Keep the face of the grinding wheel clean.

- Mount the tooth rest correctly.

- Use the correct speed and feed.

- Use coolant.

- Do not remove too much material at the same time.

In this post, we’ve discussed parts of tool and cutter grinding machine, their types, uses.

I hope you like this post.

Thank You.

0 Comments