Hello friends, welcome you all to my site Mechical.

Today’s topic is related to the manufacturing processes and here we are talking about a forging process.

In which we will know in detail the types of forging process, accessories of forging, and various forging operations.

The forging process is a very important part of the manufacturing process which is used for making the variety of the products which are extensively used like a crank, crankshafts, and connecting rods for the automobile.

Also, wrenches or spanners are used for assembling and disassembling purposes, crane hooks, etc.

So let's start today’s topic Forging Process

Definition of Forging Process

Forging is one of the oldest methods to produce shapes from red-hot metal.

Generally, hammers are used for shaping the parts of an object.

The forging process can be defined as the process which deforms the permanent metal and gets in the desired shape.

The forging process is one of the types of forming process.

Clearly seen in the figure where the blacksmith deforms the red hot metal and gets into the desired shape.

|

| Black Smith Forging |

Classification of Forging

It can be classified into three categories which are:

- Cold Forging

- Warm Forging

- Hot Forging

Cold Forging

In this method, forging is done at atmospheric or room temperature.

Warm Forging

In this method, forging is done above atmospheric or room temperature but below the recrystallization temperature of matter.

Hot Forging

In this method, forging is done above the recrystallization temperature of matter.

Types of Forging Process

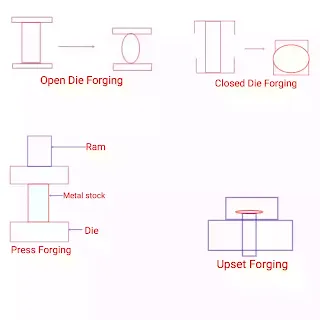

Forging can be divided into four parts which are:

- Smith Forging or Open Die Forging

- Drop forging or Closed Die Forging

- Press Forging

- Machine Forging or Upset Forging

Smith Forging or Open Die Forging

Smith forging is basically related to the blacksmith who lives in villages earlier, this is the traditional method.

Blacksmith used to heat the metal stock and heated metal stock is repeatedly beaten to manipulate the flow of molten metal so as to get the desired size and shape.

Smith forging largely depends upon the skill of the blacksmith.

So for this smith forging process, the skill of the operator or skill of the blacksmith is very important.

Another thing is that this process is good for the small volume that means when few numbers of the products are to be made, not for the very large volume because if you have to make very few numbers of the products, then making the die will be a costly issue.

So, It will be important that instead of making the die for making a few products, it is better to use the smith forging process so that it can be made economically.

Drop Forging or Closed Die Forging

In a smith forging process basically, flat surfaces are used.

While in the case of the drop forging, close dies are used.

So, here according to the shape of the product to be made, we will have to make it by upper die and lower die. So, this will be placed over the table of the press.

After placing the metal between the die then force is applied through the upper die onto the stock until the die closes.

So, here the force is applied in a repeated manner means three to four numbers of the impacts are applied onto the stock with the help of the upper half of the die so that the die is closed.

Once the die is closed, we will be getting the product of the shape.

Press Forging

Press forging also uses the close dies means an upper and a lower die and the metal is placed between the upper and the lower dies.

So after the application of the pressure, the dies are closed and the shape is desired.

In the earlier case, in drop forging impacts were applied in a repeated manner through the upper die but in this case, continuous increasing pressure by squeezing action.

Here the smoother surface is generated in the press forged products as compared to the drop forged products.

Machine Forging or Upset Forging

Machine forging is basically used for making the head of the bolts.

So at the top, if we need to bolt, we need to upset and make the head.

For making the heads of the bolts, this process was initially used, and thereafter it has been used for making many other products like the axles, spindles, and the number of the components having the like where is upsetting is needed.

The axles, spindles, head of the bolts are the common examples of machine forging products.

During the forging process, we found desired shape and at the same time also some portion of the metal’s properties has changed so you also must know about the mechanical properties of materials or metals.

In the forging process, there are so many types of forging operations performed with the help of forging accessories and forging tools.

So, let’s know about accessories of forging and forging tools before knowing forging operation.

Accessories of Forging

Forging has different accessories here we discussed the most important accessories which are known by forge and are discussed below

•Forge

Forge

Forge is a type of furnace in which, the job is placed for heating.

The forge supplies heat to raise the temperature of the metal to be forged.

It is made up of a mild layer of steel and angle in which the tuyer coal tank is made from fire bricks and clay.

There are two types of forge such as

- Stationary Forge

- Portable Forge

Types of Forging Tools Used in Forge

Different types of forging tools are used with forge, which is as follows.

- Blower

- Rake

- Shovel

- Poker

- Sprinkler

- Fuels

Blower

For proper combustion of fuel, an efficient and adequate supply of air at proper pressure is required, which is fulfilled by a blower.

Generally, it is used, when a small quantity of air is needed.

Rake

It is used to pull the charged fuel over the job, It has a rectangular shape of flat bent in the front side with 90°.

Shovel

It is used to place coal or coke in the furnace as well as remove ash from the furnace.

Poker

It is used to remove clinkers from the furnace. It is a rod at which one end pointed and turned.

Sprinkler

It is used to localize the heat. The outer ring of the fire is kept wet so that, the heat is concentrated in the middle of the hearth.

Fuels

For heating the metal, many fuels are used. The most common fuels are coal, coke, charcoal, oil, and fuel.

Types of Forging Tools Used in Smithy Shop or Forging

Many types of forging tools are used in smithy shops other than forge, which is discussed below

- Anvil

- Swage Block

- Tongs

- Hammer

- Chisel

- Swage

- Fuller

- Flatter

- Punch

- Drift

- Leg Vice

Anvil

The anvil is a heavy block of cast steel, which is used in forging sheets.

Swage Block

It is a square block made up of cast iron or steel.

Tongs

Tongs are made up of mild steel or medium carbon steel.

These are used for keeping the heated metal piece as well as for gripping or turning the workplace during forging.

Hammer

A hammer is a tool that is used to strike, crush and hammer the job.

According to the different shapes of hammers, they are classified into three types which are as follows

- Hand Hammer

- Power Hammer

- Sledge Hammer

Chisel

Chisels are made up of high carbon steel.

There are different types of chisels and each has a particular use, which is as follows

- Cold Chisel

- Gauge Chisel

- Hot Chisel

Swage

Swage is used to reduce or finish round, square, or hexagonal forms.

It is made with half grooves of dimensions to suit t work being reduced.

Fuller

Fullers are made up of high carbon steel having different types of shapes.

It is used for grooving and drawing down the thin portions of forging against the shoulder.

Flatter

It is made up of high carbon steel and is available in various sizes from 50 to 75 mm.

It is similar to the hammer and its down parts are flat and wide. It is used to make the surface of the metal flat.

Punch

Punches are the types of marking tools that are used to make holes of any shape and size (round, square, or rectangular) on hot and cold metal.

Drift

Drifts are made up of steel tool, which is hardened and tempered.

It is used for finishing the size of the punched holes. They are made taper and bulging in the at the center.

Leg Vice

Leg vice is used in a forging process for bending work.

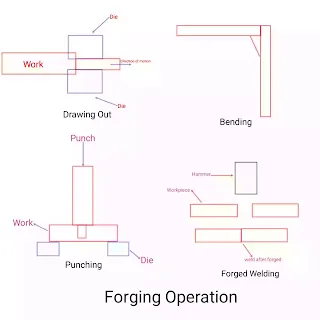

Forging Operation

In forging operation By the help of forging tools and heating effect, we can change the shape of a substance according to the requirement, which are:

- Drawing Out

- Upsetting

- Bending

- Punching

- Drifting

- Forge Welding

- Cutting

Drawing Out

Drawing out is used to reduce the thickness of a bar and increase its length.

Upsetting

Upsetting is a forging operation by which the length of a piece of metal is reduced, and its cross-sectional area is increased.

This is the most widely used in forging processes.

Three types of upsetting are applied in forging such as

- End Upsetting

- Jumping

- Center Upsetting

Bending

It is a method by which steel may be bent to form various shapes without damage to its structure.

The method of bending involves the use of an anvil edge, a block of metal held in the Hardie hole or in a vice.

Punching

This process is used for making holes in metal plate, which is placed over the hollow cylindrical die.

By pressing the punch over the plate, the hole is done.

Drifting

It is the process, which is used for finishing the size of the punched hole with the help of drifts.

Forge Welding

In this operation joined two metals through heating and hammering.

There are four types of joints made by welding such as but joint, lap joint, V-joint, T-joint.

Forge welding joint more strongest than soldering and brazing.

Cutting

It is a method to cut metal by chisel and hammer when the metal is gaining high temperature and visible as a red.

Advantages and Disadvantages of Forging Process

Advantages of Forging

- Forge parts possess high ductility and offer great resistance.

- Forging refines the structure of the metal.

- The forged part metal welding is so easy.

Disadvantages of Forging

- Tolerance is not maintained accurately in this process.

- Some materials do not properly work by forging.

- The initial and maintenance cost of forging dies are very high.

In this topic, I have talked about the forging process and its types, operation, etc.

If have any doubt then ask me through the comment.

FAQ For a Forging Process

Roll forging is done with the help of?

Roll forging is the type of forging which is done with the help of cylindrical and as well as semi-cylindrical rolls.

Which of the following forging process is used by blacksmiths found in villages?

Smith forging which is also known as open die forging generally done by blacksmith which lives in villages.

What is smith forging?

Smith forging is a type of forging process which is done by a blacksmith and it's also called open die forging.

In which forging process, parts are heated in open hearth?

Parts are heated in an open hearth by the smith forging process which is also called hand forging.

In which forging process, parts are heated in closed hearth?

Parts are heated in a closed hearth by drop forging process which is also called closed die forging.

Drawing out is a forging operation used?

Drawing out is a forging operation used to increase the length of a bar and reduce thickness.

Which of the forging operation is used to form heads on bolts?

Forging operation is used to form heads on bolts by upset forging which is also called machined forging.

Which type of forging is done by deforming the metal at room temperature?

The type of forging is done by deforming the metal at room temperature is called cold forging.

Swaging is another name for which smith forging operation?

Swaging is nothing but it is a drawing-out operation that increases the length of metal or bar and decreases thickness.

The forging process that is generally used for producing hexagonal or round heads of bolts is?

The forging process that is generally used for producing hexagonal or round heads of bolts is called upset forging.

Drop forging is used to produce?

Drop forging is generally used to produce hammers, spanners, wrenches, and is also used to make a part of vehicles, airplanes, etc.

What is hand forging?

Hand forging is nothing but it is Smith forging which is also known as open die forging.

For which purpose, hand forging is used?

Hand forging is basically used where a small amount of product is required to be made.

And also this forging process is less costly as compared to other forging processes.

In forging the material of anvil is/are?

In forging the material of anvil is used cast steel.

The forging operation of upsetting is?

The forging operation of upsetting is generally used to make a head of the bolt.

What is the process of forging?

The forging process is a type of manufacturing that shapes the metal through particular deformation.

What are the different types of forging processes?

There are so many types of forging like, smith forging, closed die forging, press forging, etc.

Which type of forging is done by blacksmith?

Open die type of forging is done by blacksmith which is also called smith forging.

What are the advantages of forging process?

Through the forging process, achieving the desired shape and also improving properties of materials.

What is roll forging?

When metal is passed through in between driven rolls then metal is pressed and found the desired shape this type of forging is known as roll forging.

0 Comments