Hello friends, Today I am going to tell you about Vices which is mostly used in industries or workshop.

In these topics, we will know about the types of vices used in workshop and also we will learn about clamp devices.

Vices are used to hold the tool or a job in a workshop, when performing any

operation like drilling, filing, taping, grinding, milling, etc.

These types of operations are performed on a specific machine through a cutting tool like drilling is done by drill bits, grinding is done by grinding wheel, etc.

And for making cutting tools, different types of cutting tool materials are used like carbon steel, high-speed steel, etc.

Because of its mechanical properties are of high strength and hardened.

So, let's get started to know the types of vices used in workshops.

What is Vice?

Vice is a job holding tool, which is used to hold the job firmly in the workshop.The Vice is used to tightly hold the job while performing operations in workshops like a filling, cutting, drilling, tapping, dyeing, etc.

Types of Vices

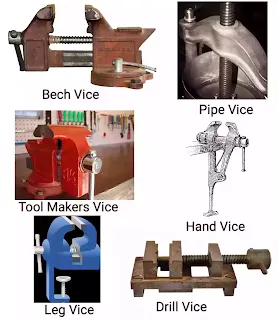

There are the following types of vices used in the workshop:- Bench Vice

- Pipe Vice

- Tool Makers Vice

- Hand Vice

- Leg Vice

- Drill vice

- Pin Vice

|

| Different Types of Vices Used in Workshop |

Bench Vice

This is a job holding device that is often used to hold the tasks while performing operations such as sawing, filing, chipping, tapping, external threading, etc.It is fitted above the bench.

There are two steel jaws on this vice that are hardened and have grooves on them.

Its size is taken from the width of the jaw.

Its fixed jaw remains fixed and only the movable jaw moves and tightens the work when the spindle is tightened.

To hold the finish works, regular jaws (jaws) should be coated with aluminum, brass, or copper to prevent the finished surface of the work from deteriorating.

It is also called machine vice when it is fitted with a machine.

Bench Vice Parts and Functions

There are following parts are attached to the bench vice:- Fixed Jaw

- Movable Jaw

- Jaw Plates

- Spindle

- Handle

- Box Nut

|

| Bench Vice Parts |

Fixed Jaw

Fixed Jaw is always fixed in the bench with the help of a nut and bolt.A fixed jaw is made with grey cast iron.

Movable Jaw

Movable Jaw moves back and forth according to the size of the job.Movable Jaw is also made with grey cast iron.

Jaw plates

The jaw has a plate inside, which is fixed by a screw is known as a Jaw plate.These plates are fitted with cross-cuts, which create a grip on the job.

For making these plates carbon steel's metal is used.

Spindle

The movable Jaw has to consist of a spindle, which is made of mild steel.The movable jaw moves back and forth only when this spindle rotates.

Handle

Handle is fitted with the spindle and then rotates the handle clockwise and anticlockwise direction then the spindle moves forward and backward.The handle is made of mild steel.

Box Nut

The nut that the spindle passes through is called the box nut as well as the guide nut.Box nut always fits in the fixed jaw.

It is made of cast iron or gun metal.

Points to be Noted While Fixing a Bench Vice

1. The height of the vice should be one meter from the shop floor to the top of the vice or equal to the artisan's elbow.2. It is advisable to fix the bench vice with bolts, nuts, and washers above the top of the bench as it provides good support and strength.

3. It should be at the level and parallel to the vice job work bench and shop floor. If it is not fixed to level then the material will rub more than one side on the job.

4. Its fixed job should be slightly out of the end of the work bench.

5. The vice should be firmly fixed. If it is not held firmly, it will vibrate, affecting the surface finish and precision.

Pipe Vice

This type of vice is often used for round shape work and C clamping of pipes, especially plumbing and locksmith works.On it, the 'V-shaped groove's jaw is cut, which allows the pipes and cylindrical bars to be well gripped while performing cutting, threading, etc.

It is often fitted well at the end of the bench.

Tool Makers Vice

This type of vice is used to hold the difficult job which is in a small size while filing and machining.It can be swiveled to set the work at any angle.

Hand Vice

Sometimes it is also used to hold thin plates while drilling.

Leg Vice

This type of vice is used to perform heavy and

rough types of work such as bending, forging, and

chiseling and it can bear heavy work.Drill vice

This is a strong vice with a movable joint. It can be moved forward and backward by rolling the handle of the movable jaw.This vice is used while drilling on small pieces.

Pin Vice

This vice is used to hold a small diameter of jobs such as pins, needles, etc.

Care and Maintenance of Vices

• The sliding back should not be used as an

anvil. The vice should be tightened only by

its handle. Hammer should not be used to obtain more leverage. • From time to time, the vice should be cleaned and applied to it and check its looseness. If the jaws become loose, they should be replaced.

• When the vice is not in use, it should be kept loose.

Clamp Devices

Clamp devices are also used to hold the tool or a job.There are the following types of clamp devices found:

- Vice Clamps

- "C" Clamp

- Tool Makers Clamp

Vice Clamps

Using these jobs does not mark the marks of the vice jaws, and the finish of the work has not deteriorated.Depending on the function, these joints are found in different sizes.

"C" Clamp

It is a clamp to do all the work which is often used for all types of simple tasks.It is also used to hold jobs on an angle plate or drill machine table, and to hold two or more jobs together. A 'C' clamp of appropriate size should be used for a particular job.

It should not be subjected to excessive pressure as this may cause the screw rod to turn.

It is mostly used for marking, soldering, brazing, etc.

|

| "C" Clamp |

Tool Makers Clamp

So I hope you all know the types of vices used in workshop very well as well as clamp devices.

1 Comments