Hello friends, Today we are going to discuss the milling

machine, In which we will know all aspects related to the milling machine such as parts

of milling machine, types of milling machine and also covers the operation of

milling machine.

The most commonly used machine after

lathe machine is the milling machine.

It is also a type of manufacturing machine like drilling machine,

shaper machine, planer machine, etc.

Basically milling machine is used for making a flat surface, slots, splines,

keyways, sprockets, and gears.

Slots and keyways can also be made by slotting machine which I have already discussed.

What is Milling?

Milling is a method in which the material is cut by feeding the workpiece under a rotating multiple tooth cutter and producing a machined surface that may be flat, angular, or curved.The cutting action of teeth on milling cutters can be quickly machined.

Parts of Milling Machine

The main parts of the milling machine are following:- Base

- Column

- Knee

- Saddle

- Work Table

- Spindle

- Overarm

- Arbor

- Brace

- Milling Cutter

|

| Parts of Milling Machine |

Base

It is made up of gray cast iron whose top and bottom surfaces are machined in

precision and it acts as a foundation member for all other parts of the

machine.Column

A column is a vertical member that is cast with the base.These parts of the milling machine have an all driving mechanism for spindle and table feeds.

Its front vertical face is machined in precision and the top of the column is finished to hold the overarm.

Knee

It is a strong casting of gray cast iron that slides up and down on the vertical wedge of the column.It consists of a table feed mechanism and various controls.

A knee is used to support saddles, work tables, and workpiece clamping devices.

Saddle

The top of the knee is fitted with a saddle, which slides on the face of the column on the guideways set at exactly 90°.The top of the saddle is machined in precision to provide guideways for the table.

Work Table

A work table is the most important part of a milling machine on which the workpiece or a job holds tightly and performs many operations.The top of the table is finished in precision and 'T' slots are made to clamp the work and other fixtures.

Spindle

The spindle is located at the top of the column and rotates through receives power from belts, gears, and clutches and transmits it to the arbor.Overarm

It is mounted at the top of the column and rises in front of the column face.It is commonly used to support arbor and spindle.

Arbor

It is the extension parts of spindles on which milling cutters are held or rotated.Brace

A brace is an additional support that is fitted between the knee and the overarm to ensure greater strength for the arm and knee.Milling Cutter

It is the very most important part of a milling machine because through milling cutters different types of milling operations are performed.It is a multipoint cutting tool in a milling machine.

Types of Milling Machine

There are following types of milling machines are used:- Column and Knee Type

- Fixed Bed Type

- Planner Type

- Special Type

Column and Knee Type

Above shown in the figure the milling machines are the column and knee types.

Column and knee type milling machines can be classified into

three categories.

- Plane/Horizontal Milling Machine

- Vertical Milling Machine

- Universal Milling Machine.

Plain/Horizontal Milling Machine

It is stronger than many other types of milling machines.In these types of milling machines, the table can be fed in three directions longitudinal, vertical and crosswise.

Vertical Milling Machine

The vertical milling machine differs from the horizontal milling machine according to the spindle's position because Its spindle rotates on the vertical axis.Universal Milling Machine

A universal milling machine is similar in shape to a plane milling machine.But in addition to the movement in three directions, the table can be swiveled in the horizontal axis as well.

All types of milling work can be done on these types of milling machines.

It is used for cutting helical gears, different types of straight and taped works, etc.

Fixed Bed Type Milling Machine

It is very heavy, and its table is directly tied on the fixed bed wedge.Its table can reciprocate at right angles along the axis of the spindle.

There is no system for a cross or vertical adjustment.

In these types of milling machines, the milling cutter is mounted at the spindle head which can move vertically on the column and the spindle also can be adjusted horizontally to provide cross adjustment.

Planer Type Milling Machine (Plano - Miller)

It is large in shape and is used for heavy duty work.Spindle heads can be adjusted vertically and in transverse directions.

Special Type Milling Machine

There are following special types of milling machines are used:- Surface Milling Machine

- Thread Milling Machine

- Gear Milling Machine

- Copy Milling Machine

Surface Milling Machine

This milling machine is used for multi-production work.Its spindle head can be adjusted vertically with a milling cutter.

In these types of milling machines, the feed movement is given by the table.

Thread Milling Machine

A thread milling machine is used for the milling of threads.Gear Milling Machine

A gear milling machine is used for the milling of different types of gear.Gear teeth are often cut by milling with the help of a dividing head.

Milling of small gears can be also done on a horizontal milling machine but special gear machines are required for milling larger gears.

Copy Milling Machine

It is used to make workpieces that have irregular surfaces.Work Holding Devices for Milling Machine

There is the following work holding devices often used to hold the work on the table of the milling machine.- 'T' bolts and clamps

- Angle plates

- 'V' blocks

- Vices

- Special fixtures

You can also read Work holding devices in lathe machine which I have talked about in the previous post.

Now we will discuss the operation of the milling machine,

But before knowing this first of all I suggest you read the types of milling cutters and their uses which I have already discussed so that we can better understand the operation of the milling machine.

Operation of Milling Machine

The commonly used milling operations are described below.- Plain Milling

- Face Milling

- Side Milling

- Straddle Milling

- Angular Milling

- Gang milling

- Form Milling

- Profile Milling

- End Milling

- Saw Milling

- Milling of Keyways, Grooves, Slots

- Gear Cutting

- Helical Milling

- Cam Milling

- Thread Milling

Plain Milling

Plain milling is an operation of a milling machine in which a plane, the flat horizontal surface is drawn parallel to the axis of rotation of the plane milling cutter.This is also called slab milling.

Face Milling

These types of milling operations are done by a face milling cutter which rotates in the vertical direction along the axis of the work surface.

Side Milling

Side milling is an operation of a milling machine in which the flat surface is made on the side of the workpiece using a side milling cutter.Straddle Milling

Straddle milling is an operation of a milling machine in which flat vertical surfaces are made on both sides of the workpiece using two side milling cutters tied on the same arbor.Angular Milling

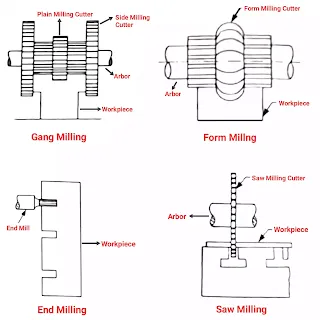

Angular milling is an operation of a milling machine in which the angular surface is formed on the workpiece at an angle other than the right angle along the axis of the spindle of the milling machine.Now, See in figure gang milling, form milling, end milling, saw milling operations which are described below.

|

| Operation of Milling Machine |

Gang milling

A gang milling is a type of milling operation in which several surfaces are

machined on the workpiece, using one diameter or different diameter cutters

together on the machine arbor.Form Milling

Form milling is a type of milling operation in which irregular contours are made using form cutters.Irregular contours that can be convex, concave, or any other shape.

Profile Milling

This is an operation in which a complex-shaped outline of a template or master die is created on a workpiece.End Milling

End milling is an operation in which a flat surface is made which can be vertical, horizontal, or at any angle.

Saw Milling

Saw milling is a type of milling operation in which narrow slots or grooves

are made on the workpiece using a saw milling cutter.Milling of Keyways, Grooves, Slots

Keyways, grooves, and slots can be made on a milling machine using a plane milling cutter, slitting saw, end mill, or side milling cutter.Gear Cutting

Gear cutting can be done on a milling machine using a form relieve cutter.The cutter can be of the cylindrical type or end mill type.

Helical Milling

Helical milling is an operation of a milling machine in which helical flutes or grooves are made at the periphery of cylindrical or conical workpieces.Cam Milling

Cam milling is a type of milling operation in which the cams are made on a milling machine using a universal dividing head and vertical milling attachment.Thread Milling

Thread milling is an operation of a milling machine in which threads are made using a single or multiple thread milling cutter.This operation is performed on a special thread milling machine to make small or large quantities of precision threads.

So friends here I discussed parts of milling machine, types of milling machine and as well as operation of milling machine.

I hope you all clearly understand all aspects related to this topic.

0 Comments