Hello, friends in this topic I will talk about the Operation of Lathe Machine.

Before knowing the operation of lathe machine, First of all, we have to know important parts of the lathe machine, So that we can better understand the operation of lathe machine.

Lathe machine is the most versatile machine, which is widely being used in industries.

The main purpose of the Lathe machine is to rotate a workpiece or a job to give the desired shape by performing some operations on a lathe.

There are so many types of lathe machines used in industries such as Bench type lathe, center lathe, capstan lathe, turret lathe, etc.

But nowadays CNC type lathe is most widely used in the industry because this type of lathe is fully automatic.

In this type of lathe one-time programming is set after that operation of lathe machine continuously performed till the end.

In this topic, we will only discuss the lathe machine as well as the operation of lathe machine.

so let's start

|

| Lathe Machine Operation |

Definition of Lathe Machine

A lathe machine is a manufacturing type of machine in which so many operations are performed to make any metal or part to its desired shape.

Besides this Forging, welding, casting, etc. are also part of manufacturing.

Lathe machine is consist of different types of the part which is given below.

Parts of Lathe Machine

Here we discuss some important parts of lathe machine which is useful for performing the operation of lathe machine as follows:

- Bed

- Headstock

- Spindle

- Carriage

- Tailstock

- Tool Post

- Chuck

Bed

A bed is basically the base of the lathe machine which is made of cast iron. The whole load of the lathe is tackled by a bed.

Headstock

Headstock is placed on the left side of the lathe machine.

In headstock mainly parts are attached such as Lever, gearbox, and chuck which is used to perform lathe machine operation(see in fig).

Spindle

Spindle is the part of lathe machine which provides a rotational speed of workpiece or a job.

Carriage

The carriage contains mainly five parts a saddle, apron, compound slide, cross slide, and tool post.

Carriage basically provides movement of the tool in different directions such that make any shape of workpiece or a job.

Tailstock

Tailstock is placed right-hand side of the lathe machine.

It is applied when a heavy job or workpiece is used for lathe operation than tailstock used to hold it.

Tool Post

Tool post is the part of the carriage that is used to hold any type of tool for performing an operation of a lathe.

Chuck

Chuck is one of the types of work holding device that is used in lathe machine operation for holding the workpiece or a job.

These lathe machine parts helped to perform the different operations of the lathe machine.

Operation of Lathe Machine

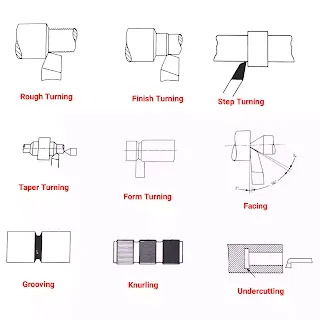

The various operation of Lathe Machine is performed such as follows:

- Straight Turning

- Rough Turning

- Finish Turning

- Step Turning

- Taper Turning

- Eccentric Turning

- Form Turning

- Facing

- Grooving

- Undercutting

- Knurling

- Relieving

- Drilling

- Reaming

- Boring

- Counter Boring

- Taper Boring

- Grinding

- Milling

- Chamfering

- Thread Cutting

- Tapping

- Parting Off

- Spinning

- Spring Winding

- Filing

- Polishing

Straight Turning

The work on a lathe is often machined for two reasons, to cut it to size and to make a perfect diameter.

The work which has to be cut in size and its diameter has to be kept the same for the entire length, then straight turning is done on it.

This is probably a more general lathe operation.

In the straight turning operation, the workpiece is turned straight when it is made to rotate about the lathe axis and the tool is fed parallel to the lathe axis.

You can clearly be seen in the figure in the turning operation where the tool feeding direction is parallel to the axis of the lathe.

This lathe operation is also known as parallel turning.

In straight turning operation cylindrical type surface is made by removing excess material from the workpiece.

It is of types such as rough turning and finishing turning.

Rough Turning

Rough turning is used to cut the waste metal as quickly as possible and to make the diameter of the work as accurate.

Finish Turning

The purpose of finish turning is to produce the work to the required size and achieve a good surface finish.

Make sure that the cutting edge of the tool used for finish turning is sharp.

It requires high cutting speed, low feed, and very low cut depth.

Step Turning

When more than one diameter is machined on a shaft, the joining section of each diameter is called a shoulder or step.

Step turning is the process of turning which produces different surfaces diameter.

The workpiece is held between centers and the tool is moved parallel to the axis of the lathe.

It is also called shoulder turning.

Taper Turning

In a taper turning the operation of the lathe machine is performed in a manner of uniform increasing the diameter of a workpiece or a job along its length.

For the taper turning, we can use the following taper turning methods

- By using from tool

- By using the compound slide

- By using taper turning attachment

- By displacing the tailstock

Eccentric Turning

If any cylindrical job has two or more in different types of axis and their centers are different from its axis, it is called eccentric workpiece components.

The process of turning such as eccentric components is called eccentric turning.

Form Turning

Form turning is a method of turning curved or irregularly shaped surfaces on a lathe.

Facing

Facing is a process in which a flat surface is formed by cutting metal at right angles to the axis of the lathe.

The tool should be set such that its cutting face makes an angle of about 2º with the metal surface and must be centered.

In facing operation feeding tool is always perpendicular to the axis of the rotation of a job or a workpiece.

Facing operation also can be done in milling machine through milling cutters that are known as face milling.

Grooving

Grooving is an operation often called recessing.

It is often performed at the ends of the thread, on the side of the shoulder, or to enhance the appearance.

In grooving process produces a narrow groove on the cylindrical surface of the workpiece.

In grooving process produces a groove like a square, radial, and also in a beveled type shape.

Grooves are also can be made by slotting machines.

Undercutting

The process of internal cutting in a hole is called under cutting.

The undercutting is widely used for internal threading and cutting a groove.

Like threading in a nut and bolt, or internal machine part.

For this, the square nose parting tool is used.

Undercutting is done at the end of an internal thread or counter bore to provide clearance for the tool or any mating part.

Knurling

Knurling is done by pressing the two hardened steel wheels called knurls and the process of impressing the straight indentations on the surface of a workpiece is called knurling.

It is widely used for external coarse surfaces of the measurement devices, gauges, and other equipment to easy grip.

Relieving

This process is used for relieving the teeth of a cutting tool.

To do this process on the general lathe, a relieving attachment is used.

|

| Lathe Machine Operation |

Drilling

Drilling in the lathe can be done in the following two ways

- By rotating the work and feeding the drill into it.

- By rotating the drill and feeding the work to it.

In this process, the drill bit tool is used for drilling the workpiece.

After drilling, a lathe machine provides the other operations such as tapping, boring, internal threading, etc.

Reaming

Reaming is a process that consists of the accurate size, round and fine finishing of a hole after the drilling.

The tool used for this is called a reamer.

Reamer has the cutting edges and is gripped in the drill chuck.

Reaming on the lathe is done in exactly the same way as drilling is done.

For the reaming at the lathe, the workpiece is rotated at slow speed and reaming is done by tailstock head wheel.

In the reaming process, always use the coolant.

Boring

Boring is the process in which a hole made by drilling, punching, casting, or forging is enlarged and trued.

A hole cannot be made by boring.

For boring on the lathe, a special tool holder called a boring bar is used. (See in Fig.)

It can be cut deep into the metal.

Counter Boring

Counter boring is the operation of enlarging the end of the hole through a certain distance.

Taper Boring

Taper boring operation is the same as that of the external taper turning operation and is done by rotating the workpiece or a job on the chuck.

Grinding

Grinding at the lathe machine is performed by a special attachment on a moving grinding wheel for the external and internal surfaces of a workpiece.

For the external surface grinding, a workpiece is rotated between the centers and for the internal grinding, a workpiece is gripped at the chuck and then rotated.

Milling

Milling is the operation of removing metal by feeding the workpiece against a rotating milling cutter having multiple cutting edges.

For cutting keyways or groove the work is supported on a cross-slide by special attachment and fed against a rotating milling cutter held by the chuck.

Chamfering

It is performed on the edges of the faces of the outer diameters and bore diameters with a cutting tool to produce beveled edges of limited length.

It has the following objectives:

- To remove burrs and sharp edges.

- For easy assembly of mating components.

Thread Cutting

Tapping

Parting Off

Spinning Operation

Spring Winding Operation

Filing

Filing is used on a lathe to remove burrs, tool marks, and sharp corners.

Too much filing should not be done because the diameter formed by this is not in full roundness.

Generally filing lathe work is not good practice.

Polishing

This is a finishing operation that is often done to improve the surface finish of the work.

Aluminum oxide abrasive cloth should be used for polishing most ferrous metals while silicon carbide abrasive cloth is used for non-ferrous metals.

The lathe is operated at high speeds of 1500 to 1800 meters per minute.

Polishing is usually done by wrapping an abrasive cloth around the workpiece, holding the cloth by the ends, and moving it back and forth.

During polishing, a large amount of abrasive dust and metal powder collects on the parts of the lathe.

Clean the lathe thoroughly after polishing.

So friends in this topic I cover 27 different Operation of Lathe Machine as well as parts of lathe machine.

I hope you clearly understand the different types of operation which is involved in Lathe machine.

Thank you.

0 Comments