Hello friends, Today we are going to discuss types of taper turning methods on lathe machine.

Before knowing the types of taper turning methods on lathe machine, Firstly we have

to know parts of lathe machine and different types of taper which has already been discussed in the previous post.

So without wasting time let's know the types of taper turning methods on lathe

machine.

What is Taper Turning

Cutting the metal on a lathe machine in such a way that, its surface makes an angle with the axis of the metal is called taper turning.

The following are the various methods to which taper can represent.

- According to the top angle of the taper.

- mm Per meter (mm / m).

- According to the diameter of each end of the taper and the length of the taper.

- By any ratio.

Types of Taper Turning Methods

The following are the different types of taper turning methods on lathe machine.- Tailstock Set Over Method

- Compound Rest Method

- Taper Turning Attachment Method

- Form Tool Method

- Combining Feeds Method

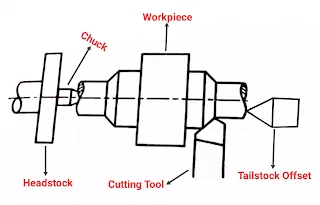

Tailstock Set Over Method

Only external tapers can be machined by this method.

In these types of taper turning methods, the tailstock is set out of alignment according to the size of the turning taper.

The clamping mechanism is loosened for offsetting, adjusting the upper part of the tailstock as required, and adjusting screws are tightened which is shown in the figure.

The amount of offset is calculated in the following way,

O = (Taper × L)/2000

Where,

0 = Offset, in mm.

Taper = millimeter/meter

L = Length of the workpiece in mm

Compound Rest Method

These types of taper turning methods on lathe machine are used for turning small and steep tapers. |

| Compound Rest Method |

After the cutting tool is set exactly at the center and brought into position by carriage movement.

The carriage is then locked and then the taper turning of the job is done by turning the handle of the compound rest by hand.

Compound rest angle can be calculated by formula,

Tan θ = D-d/2L

θ = tan-1 (D-d/2L)

Where,

D = Larger diameter of the taper

d = Smaller diameter of the taper

L = Length of the taper

Taper Turning Attachment Method

The taper turning attachment is an accessory that is provided with modern lathes.It is mounted behind the carriage.

It is used for taper turning or boring without tailstock offsetting.

In this taper turning method, the job is held in between the center or a chuck.

If the job is held between the centers, only the outer taper turning can be done.

|

| Taper Turning Attachment Method |

The guide bar can be swiveled on either side at a 10° angle and it can be clamped to the position by two bolts.

The taper turning workpiece is mounted parallel to the lathe bed (between the centers as shown in a figure).

Taper turning attachment forces the tool to move at a fixed angle.

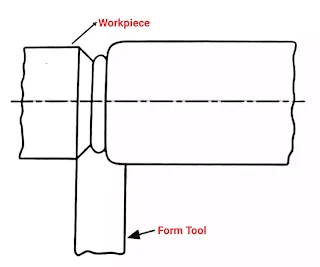

Form Tool Method

In this type of taper turning method, a straight form tool with a taper angle is set with a taper cutting edge.Show in the figure,

|

| Form Tool Method |

It is given a direct feed on the job so that it creates a definite form on the job.

The drawback of this method is that more force is not generated because more area comes in contact between the cutting edge and the workpiece.

Due to the reality of taper turning, this form tool method is only used for

short length tapers.

Combining Feeds Method

In such a method, longitudinal and cross feeds are performed simultaneously, so that the tool moves along the diagonal path. |

| Combining Feeds Method |

Methods of Measuring Tapers

There are six methods of measuring tapers in precision.- By comparing the newly turned taper with a known taper.

- Using plug gauge for internal taper and ring gauge for the external taper.

- Using the taper test gauge.

- Using gauge blocks, test mandrel.

- Using sign bars and gauge blocks.

- Using a micrometer.

I hope you all enjoy these topics.

Thank You.

0 Comments