Hello, friends today I am going to discuss riveted joints in which you will be aware of all aspects related to riveted joints such as types of riveted joints, related terms, various causes of failure, etc.

But before knowing the types of riveted joints first of all we have to know what is rivets and riveted joints.

So without wasting time let's get started.

What is Rivet?

Rivet is a semi-permanent fastening device, which is used to join sheets semi-permanently.

A rivet is a round metal rod.

There are mainly three parts of the Rivet: Head, Shank or Body, and Tail.

Rivet is made of soft metals such as copper, brass, etc.

By fitting a rivet in the hole of a job or plate, the method of spreading the end of its tail is called riveting.

Riveting is done by pressing the head of the rivet with the help of hydraulic pressure, pneumatic pressure, or hammer.

What is Riveted Joint?

The joining of sheets or plates of any metal by means of rivets is called a riveted joint.

Types of Riveted Joints

Mainly two types of joints are used while joining metal sheets by rivets:

- Lap Joint

- Butt Joint

See in the figure types of riveted joints which are described below in detail.

Lap Joint

When the edges of the seat or plate are placed above or below each other and joined by rivets, it is called a lap joint.

Lap joint can be divided into the following types:

- Single Row Lap Joint

- Double Row Lap Joint

- Chain Lap Joint

- Zig Zag Lap Joint

See in the figure different types of lap joints which are described below in detail.

Single Row Lap Joint

When a line of rivets is used in a lap joint, it is called a single row lap joint.

Double Row Lap Joint

When two lines of rivet are used in Lap Joint then it is called double row lap joint.

Chain Lap Joint

When multiple lines of rivets are used in the lap joint then it is called the chain lap joint.

Zig-Zag Lap Joint

When two or more lines of rivet are used in lap joint in a zig-zag shape then it is called zig-zag lap joint.

Butt Joint

In this, the ends of the sheet or plate are joined together, by placing a separate piece of the sheet on top of it, and this piece of sheet is called a strap.

In this, two sheets or plates touch each other but do not overlap.

The butt joint can be divided into the following types:

- Single Row Single Strap Butt Joint

- Single Row Double Strap Butt Joint

- Double Row Double Strap Butt Joint

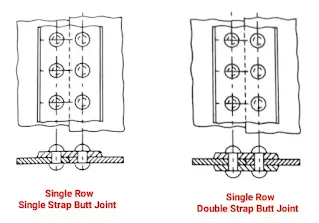

See in the figure different types of butt joints which are described below in detail.

Single Row Single Strap Butt Joint

When one row of rivets and one strap are used on both the sheets to be joined, it is called a single row single strap butt joint.

Single Row Double Strap Butt Joint

If one row of rivets and two straps are used on both the sheets to be joined, then it is called a single row double strap butt joint.

Double Row Double Strap Butt Joint

If two rows of rivets and two straps are used on both the sheets to be joined, then it is called a double row double strap butt joint.

Terms Related to Riveted Joint

There are the following terms related to riveted joints:

- Pitch

- Diagonal Pitch

- Back Pitch

- Margin

Pitch

It is the center-to-center distance between two adjacent rivets in the same row, measured parallel to the seam or edge of the plate.

Usually,

Pitch = 3 x the diameter of the rivet hole or rivet after riveting.

Diagonal Pitch

This is the transverse measurement between the centers of rivets in adjacent parallel rows on the same plate.

Back Pitch

This is the distance between rows of rivets, measured parallel to the seam.

Margin

It is the shortest distance between the center of the rivet hole to the edge closest to the plate.

It is usually kept equal to 1.5 x the diameter of the rivet hole.

Common Causes of Failure of Riveted Joint

| Reasons for Failure | Remedies |

|---|---|

| The diameter of the rivet of the plate thickness is too small, the diameter of the rivet must be greater than the thickness of the plate to which it is to be placed. | Select the correct diameter of the rivet according to the thickness of the plate. |

| The diameter of the rivet is much larger than the thickness of the plate. Rivets have a tendency to crush the metal in front of them when they are driven. | Select the correct diameter of the rivet according to the thickness of the plate. |

| Punch or drilled rivet holes too close to the edge of the plate. A crack in the front of the rivet may cause the metal to fail. | Drill or punch the rivet holes at the correct distance from the edge and use the correct lap allowance for the diameter of the rivet chosen. |

| Weakening of plates due to making rivet holes too close to each other. The plates have a tendency to break along the center line of the rivets. | Drill or punch the rivet holes to the correct spacing or pitch. In addition, before the final assembly, clean all burrs, etc. from the holes. |

So here I discussed types of riveted joints, terms related to riveted joints, causes of failure of riveted joints, and remedies.

I hope you all enjoy this topic.

Thank You.

0 Comments