Today you will learn about locating devices in which you will learn what are locating devices? Know the different types of locating devices as well as the locating methods.

So without wasting time let's get started.

What are Locating Devices?

Locating devices are usually made of case-hardened steel and separate from the jig or fixture; accurately ground and accurately positioned in the jig or fixture body.

Pins of various designs that are made of hardened steel are the most common locating devices used to locate work pieces in jigs or fixtures.

The shank of the pin is press-fitted or driven into the body of the jig or fixture.

The locating diameter of the pin is made larger than the shank to prevent it from being forced into the jig or fixture body due to the weight of the workpiece or cutting forces depending upon the mutual relation between the workpiece and the pin.

Locating devices are also called as locating pins.

Types of Locating Devices

Locating devices or locating pins can be divided into the following types:

- Locating Pins

- Support Locating Pins

- Jack Pins

- Vee Locators

- Diamond pin locator

Locating Pins

When reamed or finally finished holes are available in the workpiece, these can be used for locating purposes.

These are two types of locating pins:

- Cylindrical Locators

- Conical Locator

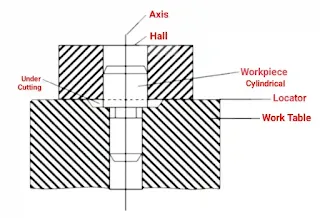

Cylindrical Locators

A cylindrical locator is shown in the figure. It is used for locating components with drilled holes.

The cylindrical component to be positioned is gripped by a cylindrical locator fitted to the jig body and inserted into the drilled hole of the component.

The body face is cut around the locator to provide space for swarf clearance.

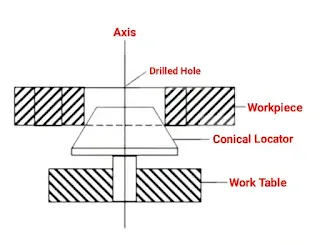

Conical Locators

A conical locator is illustrated in the figure. This is used for locating the workpieces having a cylindrical hole in the workpiece.

Conical locator is also called conical locating pins.

The workpiece is found to be positioned by placing it over a conical locator inserted into the drilled hole of the workpiece.

A conical locator is considered super because it has the ability to accommodate small variations in the diameter of a component's hole without affecting the accuracy of the location.

The degree of freedom along the z-axis can also be restrained by putting a template over the workpiece with the help of screws.

Support Locating Pins

With these pins (also known as rest pins) buttons or pads, the workpiece with flat surfaces is supported at convenience.

Fixed support pins have the locating face either ground flat or curved.

Support pins with flat heads are usually mounted and provide space and support to the machine surface, as more contact areas are available during placement.

This will ensure accurate and stable locations. Spherical head or round headrest buttons are used to support rough surfaces (without machined and cast surfaces) because they provide a point support that can be stable under these conditions.

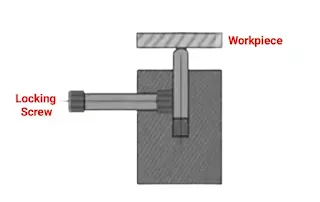

Jack Pins

Jack pins or spring pins are also used to locate the workpiece whose dimensions are subjected to variation.

The pin is allowed to come up under spring pressure or conversely is pressed down by the workpiece.

When the workpiece is secured in place, the pin is locked in this position by means of a locking screw.

V Locator

It is used to locate the circular and semi-circular types of workpieces as shown in the figure.

The core of the locating device is a V-shaped block normally attached to a jig. This locator can be of two types the first one is a fixed V locator and the second one is an adjustable V locator.

The fixed-type locator is normally fixed on the jig and the adjustable locator can be moved axially to provide the proper grip of the V band to the workpiece.

Diamond Pin Locator

This is used for workpieces with holes drilled, use two round pins.

If there is a dimension variation between the center-to-center distance of the hole, a round and diamond pin locator is used for binding.

The ends prevent movement around the pin and are relieved on two sides to allow fluctuation.

General Methods of Locating

Following are the different methods of Locating:

Locating by flat surfaces

Locating by holes

Locating from Irregular Surfaces (External)

Nesting locator or cavity locator

Profile locators

So here you have to know all aspects related to locating devices. If you have any doubts then you are free to ask me by mail or on the contact us page.

Thank You.

0 Comments